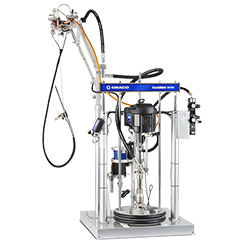

Exactablend AGP (Advanced Glazing Proportioner), advanced dosing unit for mastic and two component adhesives

Report of accurate and well dispensed dispensing

The system controls continuously the flow of the basis and adjusts automatically the flow of the hardener, allowing an accurate dispensing, during an inversion of the pump. With ExactaBlend AGP, all the distributed product is suitably mixed. A mixture which hardens uniformly and flawless. It allows to reduce the risks of break of the sealing of the insulating glass and to ensures a better quality of the final products.

Optimal mixture

For an insured quality. With the AGP U100, all the distributed product is suitably mixed; a better mixture gives a product which hardens uniformly and flawless.

Easy functioning

Compared with the traditional units of dispensing with mechanical coupling and oscillating arms, the electronic commands of the system AGP U100 eliminate the guesses in the regulation of the reports of dispensing and allow to change them easily. Next to the traditional units of dispensing with mechanical coupling and oscillating arms, the electronic controls of the system eliminate the guesses in the regulation of the report of dispensing.

Fast and easy Configuration – the operator simply enters the report basis/ hardener desired

Very easy to modify

Guarantee of reports of accurate dispensing

A simple blow of eye in the green light, now available by default, is enough for allowing the operator to know that products are distributed according to the indicated dispensings. In case of bad dispensing, the system stops automatically.

Loss produces reduced

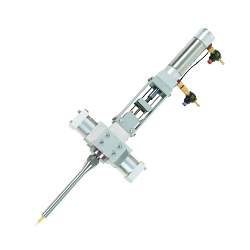

The rinsing of the base of the AGP U100 is simple and reduced the loss of product. The rinsing of the base is fast, clean and easy. It is made of a simple pressure on a button. When ExactaBlend AGP is coupled with the valve MD2, the base and the hardener are mixed in the mixer, the output of the applicator. It reduces considerably the quantity of basis purge product , necessary to clean the mixer. Furthermore, the use of the valve MD2 allows to avoid damaging the applicator and the tips if the product dried. The basic purge is fast, clean and easy. You just have to press on a button.